The freezing air shaker is a high-precision biochemical instrument organically combined with the function of temperature controlled incubator (5 ~ 50 ℃) and a high-capacity shaker. A circulating fan is added inside to force air circulation. The temperature distribution is more uniform and the experimental effect is better.Optional with light or without light function. The instrument is widely applicable to biological genetic engineering, medicine, agriculture, forestry, environmental science, animal husbandry laboratories of fisheries and other departments.

Product Features:

The inner is made of high-quality stainless steel. The freezing air shaker adopts high-performance microcomputer control, touch keys, and the panel adopts large window with blue screen LCD display, the timer, temperature and revolution can be observed at the same time,very easy operation.

Main Technical Data:

Temperature control range:5-60 ℃(with both cooling and heating function)

Timing:1-99 min

Temperature resolution:0.5℃

Temperature eveness:1℃

Shaking frequency:40-280 rpm

Shaking amplitude:25 mm,orbital shaking mode.

Power supply:220V/50Hz

| Model | HZQ-Q | HZQ-QX | HZQ-FX | HZQ-XX |

|---|

| Load Capacity (L) | 130 L | 210 L | 360 L | 760 L |

| Overall Size (mm) | 1200 * 550 * 680 mm | 1400 * 700 * 680 mm | 1500 * 850 * 690 mm | 1800 * 1200 * 9669 mm |

| Working Chamber (mm) | 630 * 550 * 550 mm | 890 * 570 * 550 mm | 1050 * 720 *550 mm | 1280 * 1080 * 550 mm |

| Bottom Plate Size (mm) | 420 * 380 mm | 800 * 500 mm | 980 * 650 mm | 1200 * 1000 mm |

| Working Power (W) | 480 W | 510 W | 600 W | 680 W |

| Bottle Clip Capacity (recommended): | Ordinary Spring Clip

or 100 ML * 28 pcs

or 250 ML * 20 pcs

or 500 ML * 9 pcs |

Ordinary Spring Clip

or 100 ml × 68 pcs

or 250 ml × 40 pcs

or 500 ml × 35 pcs |

Ordinary Spring Clip

or 1000 ml × 30 pcs

|

Ordinary Spring Clip

or 1000 ml × 40 pcs

|

How to Use:

1. Medium speed use in the speed range can prolong the service life of the instrument.

2. The freezing air shaker shall be placed on a flat ground, and the environment shall be kept clean and tidy, ventilated and dry.

3. Before using the instrument, first set the speed regulation to the minimum position and turn off the "oscillation switch".

4. Load the culture test bottle: ① pay attention to uniform distribution. ② Pay attention to sealing the test bottle mouth. ③ Prevent condensed water droplets from dropping into the test bottle.

5. Turn on the external power supply, turn the power switch to the "on" position, and the indicator light is on.

6. Temperature control:

① Turn on the power supply and the self-test ends in about one minute. If "000" is displayed, it indicates that the sensor is open circuit or the input signal exceeds the measurement range.

② Press the set key to set the temperature. Press the set key until the data on the lower row of the convergence tube flashes, indicating that the instrument enters the temperature setting state. Press the △ key to increase the setting value, press the ▽ key to decrease the setting value, and then press the set key to return to the normal working state. The temperature setting is completed.

③ When confirming that the value displayed by the instrument is not the correct measured value, the displayed value can be corrected. Press the set key for 3 seconds to enter the inner menu of the instrument. After selecting the parameter SC, cooperate with the △ or ▽ key to modify this parameter. The correction range of sensor error is 50 to - 50, after the correction is completed, press the set key for 3 seconds to exit. When the instrument leaves the factory, the correction value is 0. When using, it is necessary to prevent the instrument with correct display from being corrected to incorrect.

④ Self tuning function of the instrument: This product can adapt to most control systems. Only when the control effect is particularly unsatisfactory, you can start self-tuning. Press the set key for 3 seconds to enter the inner menu of the instrument. After selecting the parameter at, cooperate with the △ or ▽ key to start self-tuning. At this time, the at indicator light starts flashing, and the instrument enters the working state of automatic setting parameters. The instrument control heating system fluctuates twice near the set point. When the at light is off, the self-tuning ends, The new PID parameter is locked in the chip.

7. Turn on the shaking switch, the indicator light is on, and slowly adjust the speed regulation to the required speed.

8. After work, set the temperature control key and speed regulation key to the minimum value and cut off the power supply.

Maintenance:

1. Correct use and attention to the maintenance of the instrument can prolong the service life of the instrument by making it in good working condition.

2. The instrument shall be well grounded to avoid accidents. All kinds of solutions are strictly prohibited from entering the main engine room to avoid damaging the main engine.

3. The bearing of the transmission part has been filled with an appropriate amount of grease before leaving the factory. During the continuous operation of the full temperature oscillator, the grease should be filled every six months, accounting for about 1 / 3 of the bearing space.

Cutomized Items:

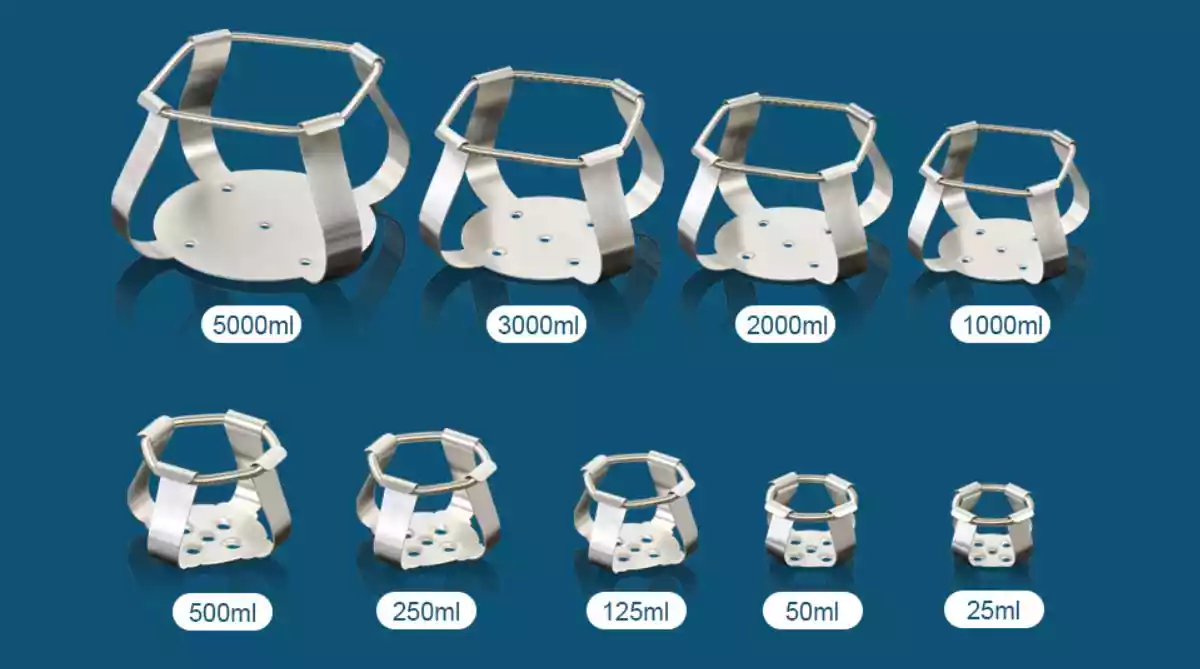

1.Bottle clip size from 25-5000ml,material SS 304.

2.Light Function

Bottle Clip Details: