This shaker has the advantage of large amplitude,large capacity, and stable speed.

Model:PZ-1000B

Technical Data:

Amplitude: 30mm, orbital shaking,eccentricity: 15mm.

Capacity: 250ml × 60 or 500ml × 35 or 1000ml × 22 or 2000ml × 16 (shaking bottle) for each layer.Total 2 layers.

Speed: 0 ~ 300rpm, AC frequency conversion speed regulation, speed digital display.

Working Area for each layer(tray size): 760 × 780mm

Overall size: 1100x760x780mm.

Motor power: 750W, AC variable frequency motor.

Overall weight: 500kg.

Power supply: AC220V ± 10%, 50Hz.

Instructions for PZ-1000b:

1. Use at medium speed in the speed range to prolong the service life of the instrument.

2. The instrument shall be placed on a stable ground with clean and tidy environment, moderate temperature and good ventilation.

3. Before using the instrument, set the speed regulating knob to the minimum position.

4. In order to make the instrument work stably and have good performance to avoid large vibration, all test bottle positions should be covered during bottling, and the culture medium of each bottle should be roughly equal. If the number of culture bottles is insufficient, the test bottles can be placed symmetrically or filled with other test bottles with the same amount of solution.

5. Select timing and adjust the timing knob to "timing" or "normally open" position.

6. Turn on the external power supply, turn the power switch to the "on" position, and the indication light is on. Slowly adjust the speed regulation knob to the required speed.

7. Before each shutdown, the speed regulating knob must be set to the minimum position, turn off the power switch and cut off the power supply.

Maintenance:

1. Correctly use and pay attention to the maintenance of the instrument to make it in good working condition, which can prolong the service life of the instrument.

2. During the continuous operation of the instrument, a regular inspection shall be conducted every three months: check whether there are water droplets, dirt, etc. falling into the motor and control components, and check the fuse, control components and fastening screws.

3. The bearing of the rotating part has been filled with an appropriate amount of grease (No. 1 calcium nano base) before leaving the factory. During the continuous operation of the instrument, the grease should be filled every six months, and the filling amount accounts for about 1 / 3 of the bearing space.

After long-term use, natural wear of the instrument is a normal phenomenon. After one year of use, if the instrument finds abnormal noise of the motor, wear of the bearing of the transmission part, looseness or crack of the belt, failure of electric control components and other faults, we will continue to provide high-quality services and assist in handling them.

Since the bottling quantity and bottling specification are ever-changing, it is very normal for users to have other bottling quantity / specification requirements. We can customize them according to users' requirements.

Cutomized Items:

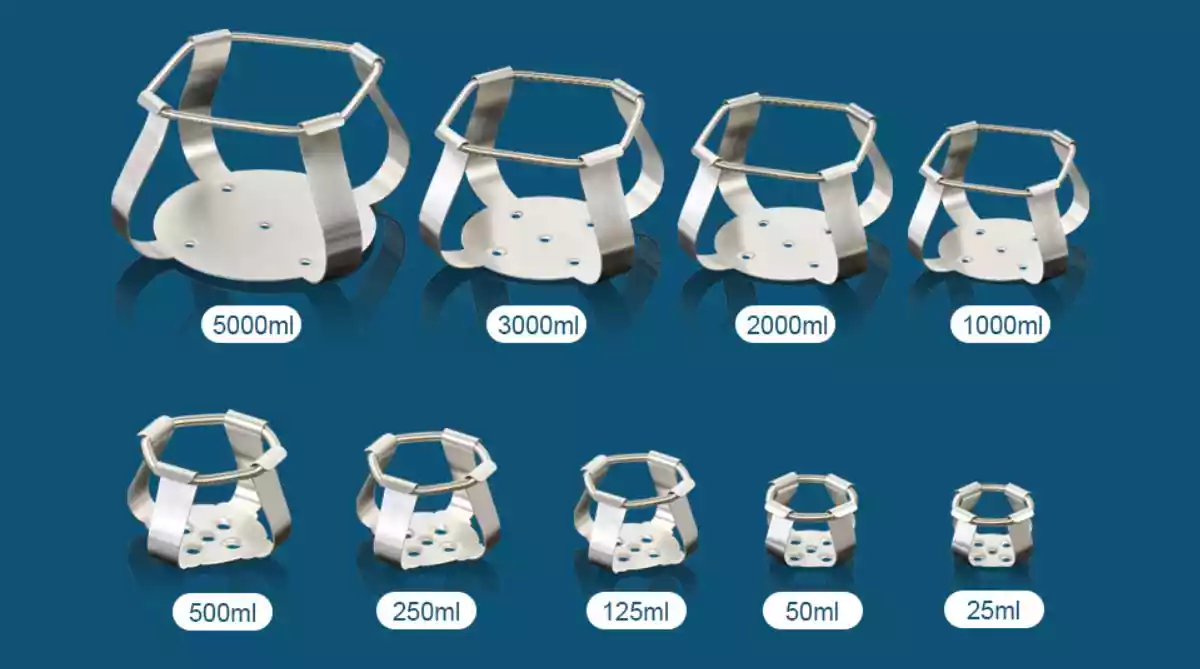

1.Bottle clip size from 25-5000ml,material SS 304.

2.Other shaking mode,such as horizontal shaking.

Bottle Clip Details: