TL1200 series split tube furnace has many advantages of uniform temperature,low surface temperature,heating or cooling promptly,energy saving and so on. It is the ideal muffle furnace for high temperature atmosphere sintering,atmosphere reducing,CVD experiment,vacuum annealing in Industry,Scientific research institutes,Universities, which offer Heating element of Kanthal resistance wire and double layer structure with air cooling system between the double walled housing to help the furnace heat or cool promptly, it can rise to 1000 ℃ in 30 minutes.Temperature controller is Shimaden 40-segments digital controller imported from Japan. The chamber is made of Polycrystalline alumina fibre imported from Japan, split Into two half sphere. The chamber can be opened when you need to cool the furnace immediately or change the tube.

Product Features:

(1).Temperature controller: Shimaden FP93 40 programmable segments (Shimaden fp93 made in Japan), It can separate into 4,2,1 programs, ie. 4x10 segments.FP93 has 6 PID controls, different PID are used for low,middle,high temperature for precise control.

Over-temperature and over-current protection, shutdown automatically when thermocouple is broken( it will shut down power when temperature is higher than 1200 ℃or thermocouples is broken, "ON" on the board is off and "OFF" is on)

There is Fahrenheit (F) and Celsius (C) for option.

With 485 communication interface: which can stop the furnace automatically.

(2).Cover opening protection system: overtravel-limit switch is installed to protect user, it will cut off power when the cover open.

(3).Chamber:it is imported from Japan, good performance of heat preservation, high reflectivity, uniform temperature field, good ability of anti thermal expansion and cold contraction.

(4).Heating element:This furnace is installed with excellent Kanthal A1 resistance wire to ensure uniform temperature and long service life.

(5).Leakage protection function:the furnace is installed with leakage air switch, it will cut off power automatically when electricity leak or current exceed rated current.

(6).Software controlling system:this furnace can control every parameter directly and observe PV and SV on the computer by communication interface and software, computer can draw and save

actual heating curve, it is convenient to call these dates at any time.

(7).Controlling system:

Power control: Chint; Controlled silicon:Germany Semikron 106/16E; Trigger:Phase-shift trigger

(8).Vacuum system: Vacuum level can be 10-1 or 10-4 with German molecular pump. TW-1.5 vacuum pump is for option.

(9).Gas system:floating flow meter or digital flow meter is for option to control gas Speed.

(10).Flange: with double ring sealing flanges, there are many adapter of the flanges to connect digital vacuum gauge,K25 vacuum Bellow. It can be made as hinge for removing conveniently.

(11).Cover: it is more safe and convenient to open the cover because of hydraulic lifter.

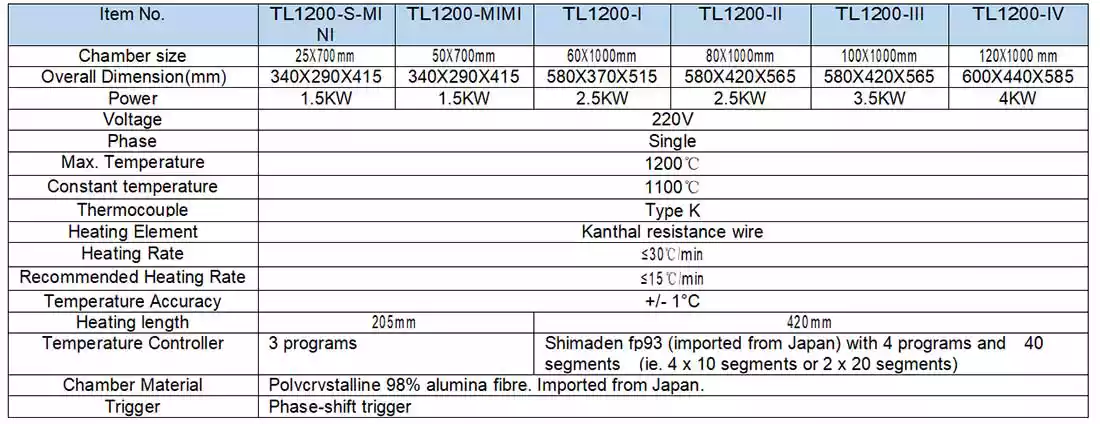

Main Technical Data: